-

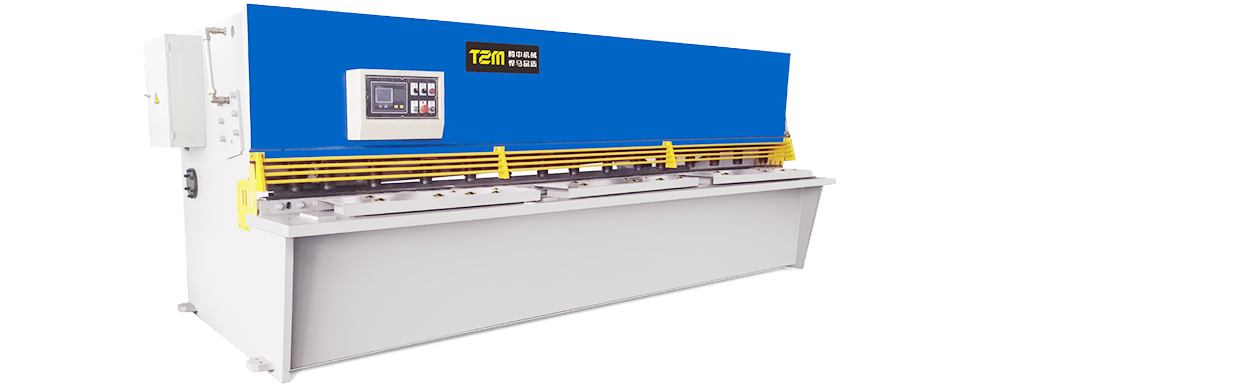

Shearing machine is a mechanical device used to cut metal sheets, also known as shearing machine or shearing machine. It mainly consists of a bed, upper knife, lower knife, transmission system, control system, etc. The shearing machine cuts the metal plate into workpieces of the required size and sh...

-

Jan 23, 2026_ShuaibiaoIntroduction to V-Grooving Machines V-grooving machine is specialized cutting tools designed to create precise V-shaped grooves on various sheet mater...Read More

-

Jan 16, 2026_ShuaibiaoUnderstanding Press Brake Machines A press brake machine is an essential tool in sheet metal fabrication, allowing precise bending of metal sheets int...Read More

-

Jan 09, 2026_ShuaibiaoWhat Is a 4 Roller Rolling Machine? A 4 roller rolling machine — also called a four‑roller plate bending machine — is a precision industrial tool desi...Read More

-

Jan 04, 2026_ShuaibiaoUnderstanding Shearing Machines and Their Importance in Metalworking A shearing machine is a critical tool in the metalworking industry used to cut sh...Read More

Safety features of shearing machine can protect operators

Shearing machine typically have several safety features to protect the operator, including:

Guarding:The machine has comprehensive guarding around the cutting blades and moving parts to prevent access during operation.This includes fixed guards, interlocked movable guards, and light curtains or other presence sensing devices.

Emergency Stops:Clearly labeled and easily accessible emergency stop buttons or pull cords that can quickly shut down the machine in an emergency.

Two-Hand Controls:Requires the operator to use both hands to activate the machine controls, preventing them from reaching into the danger zone.

Foot Pedal Actuation:Some machines require the operator to keep a foot on a pedal to enable the cutting action, ensuring their hands are kept clear.

Blade Guards:Adjustable blade guards that can be positioned close to the workpiece to minimize exposed blade area.

Pinch Point Protection:Covers or barriers to prevent access to areas where the workpiece could pinch the operator's hands or fingers.

Overload Protection:Sensors that detect excessive force or torque and automatically stop the machine to prevent damage.

Operator Training:Comprehensive training for operators on safe setup, operation, and maintenance procedures.

Warning Labels and Signals:Clear visual and audible warnings to alert the operator of machine movement or impending action.

These safety features help mitigate the risks of operating powerful metal cutting machinery and protect the operator from potential injury.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى