Unlocking Precision: What Makes V-Grooving Machines Essential in Modern Manufacturing?

2025-05-09

In the realm of contemporary manufacturing, the V-grooving machine stands as a pinnacle of precision and efficiency. Its role in transforming raw materials into meticulously crafted components cannot be overstated. But what exactly sets these machines apart and makes them indispensable in today's industrial landscape?

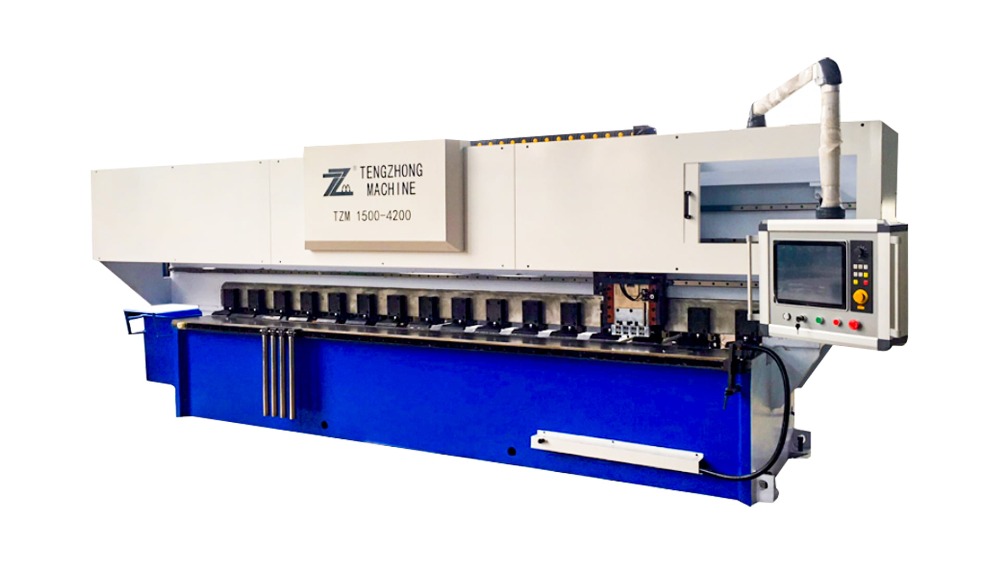

At its core, a V-grooving machine is a sophisticated tool designed to carve precise V-shaped grooves into various materials, ranging from metals to composites. This process is not merely about cutting; it embodies the fusion of engineering ingenuity with practical application, aimed at achieving unparalleled accuracy and consistency in manufacturing operations.

The anatomy of a V-grooving machine reveals a symphony of advanced components meticulously orchestrated to deliver optimal results. From the robust frame that ensures stability during operation to the intricate cutting head equipped with specialized blades, every element serves a crucial function in achieving the desired outcome.

The operational prowess of these machines lies in their ability to execute intricate designs with micron-level precision. This capability is especially critical in industries where quality and dimensional accuracy are non-negotiable, such as aerospace, automotive, and architectural sectors. Whether it's creating clean, sharp edges or preparing materials for seamless joining, the V-grooving machine emerges as a linchpin in achieving manufacturing excellence.

Furthermore, the versatility of V-grooving machines extends beyond conventional applications. They are adept at handling a spectrum of materials, including aluminum, stainless steel, and composite panels, adapting seamlessly to diverse production requirements. This adaptability underscores their significance in accommodating the evolving needs of modern manufacturing practices.

Innovation remains at the heart of advancements in V-grooving technology. Recent developments have seen the integration of automated features that enhance productivity and reduce setup times significantly. These enhancements not only streamline operations but also empower manufacturers to meet stringent deadlines without compromising on quality.

The economic implications of integrating V-grooving machines into production workflows are profound. By optimizing material usage and minimizing waste, manufacturers can achieve substantial cost efficiencies over time. Moreover, the ability to deliver consistent results fosters customer satisfaction and reinforces market competitiveness in an increasingly demanding global landscape.

Looking ahead, the trajectory of V-grooving machines points towards continued refinement and innovation. As industries push the boundaries of what's possible, these machines will evolve to meet new challenges and opportunities. Their role as enablers of precision and productivity is set to expand, reshaping the future of manufacturing with each precise groove they carve.

The V-grooving machine stands as a testament to engineering prowess and manufacturing excellence. Its ability to blend cutting-edge technology with practical application underscores its indispensability in modern industrial settings. As we navigate the complexities of a global marketplace, these machines remain steadfast in their commitment to delivering precision, efficiency, and reliability—all essential ingredients for success in the manufacturing landscape of tomorrow.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى