Mastering Metal Fabrication: The Precision Power of Plate Rolling Machines

2025-05-15

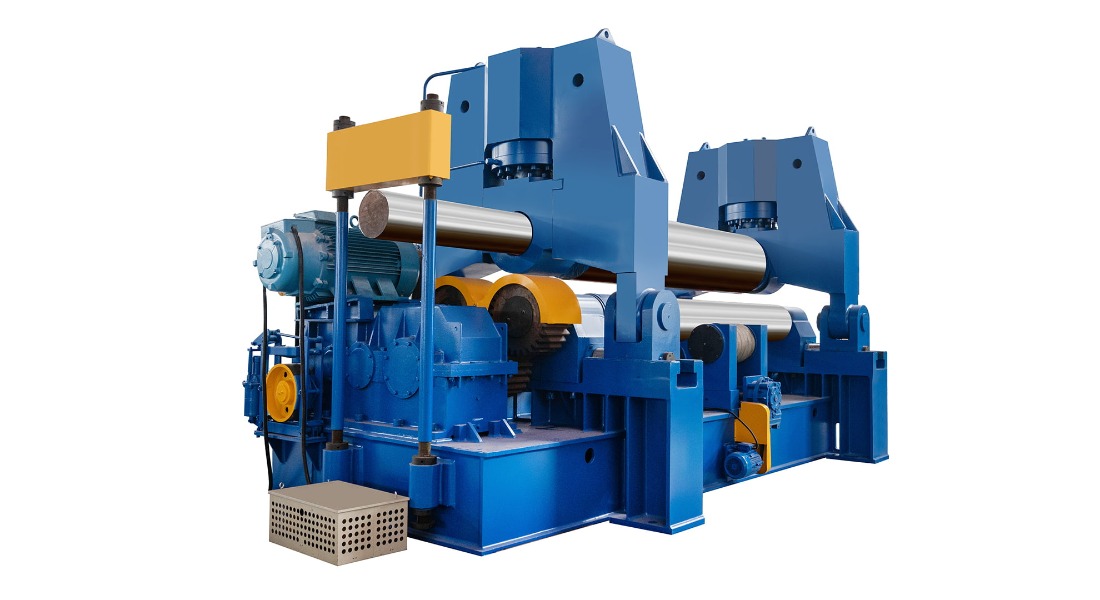

In the intricate world of metal fabrication, where precision intersects with brute force, the plate rolling machine reigns supreme. An unsung hero in industrial production lines, this formidable piece of equipment transforms flat metal sheets into perfect curves, cylinders, and cones with mechanical grace. Whether shaping structural components for bridges, crafting storage tanks, or forging architectural masterpieces, the plate rolling machine is the craftsman's tool of choice for controlled deformation.

At its core, a plate rolling machine uses a set of cylindrical rollers to bend metal sheets into desired shapes. But beneath this straightforward mechanism lies a sophisticated interplay of pressure, geometry, and material behavior. With options ranging from two-roll to four-roll configurations, each machine serves a distinct purpose. Three-roll machines, a staple in many workshops, offer versatility and precision. Four-roll machines, however, bring enhanced automation and tighter tolerances—ideal for high-volume operations demanding uniformity and speed.

Material thickness, diameter specifications, and alloy composition determine the machine's capacity. High-tensile steels, aluminum alloys, or even exotic metals—all yield under the calculated force of a well-calibrated roller. Today’s machines often incorporate CNC (Computer Numerical Control) systems, marrying old-world craftsmanship with cutting-edge technology. The result is repeatability, consistency, and remarkable efficiency.

Yet, what sets a superior plate rolling machine apart is not merely its brute strength but its finesse. A high-end machine will minimize flat ends, reduce pre-bending requirements, and ensure flawless symmetry. These factors aren’t just technical niceties—they directly impact product integrity, downstream processes, and cost-efficiency.

Safety and operational ease are non-negotiable. Modern machines are designed with hydraulic drop ends, touch-screen interfaces, automatic alignment systems, and emergency stop features. These enhancements not only protect the operator but also accelerate the production cycle, reducing downtime and boosting throughput.

Industries such as shipbuilding, aerospace, renewable energy, and infrastructure lean heavily on the capabilities of plate rolling machines. Wind towers, pressure vessels, pipelines, and marine hulls owe their precise curves to these machines. Without them, the structural and aesthetic ambitions of engineers and architects alike would remain on paper.

Investing in a plate rolling machine is not a mere procurement—it’s a strategic decision. Factors such as initial tonnage, roll diameter, machine frame rigidity, and technological adaptability must align with present and future production demands. As fabrication evolves, flexibility becomes paramount. Machines that can accommodate a wide range of materials and geometries become invaluable assets in a competitive manufacturing landscape.

In an era defined by rapid production cycles and escalating quality expectations, the plate rolling machine proves its enduring relevance. It doesn't just shape metal—it shapes possibilities. By blending force, precision, and technology, it remains a cornerstone of modern fabrication, powering industries that shape the world around us.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى