What Makes a V-Grooving Machine Essential for Modern Manufacturing?

2025-07-04

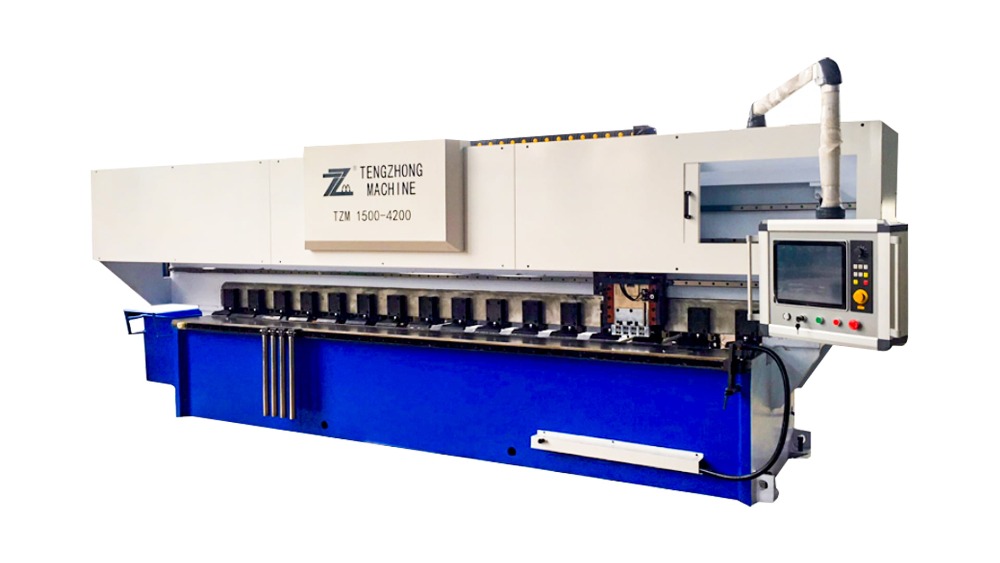

In the world of precision manufacturing, a V-Grooving machine stands as an invaluable tool, known for its unique ability to create high-quality grooves in materials like aluminum, wood, and composite panels. As industries increasingly demand intricate designs with exacting precision, this machinery has become essential in delivering superior results with remarkable efficiency. But why has the V-Grooving machine earned such a reputation? Let’s explore its features, benefits, and impact on manufacturing processes.

The Core Functionality of a V-Grooving Machine

At its core, a V-Grooving machine is designed to cut grooves with a V-shaped profile into various materials. These grooves serve multiple purposes, including enhancing the material’s flexibility, reducing weight, and improving aesthetic appeal. By utilizing a rotating cutting tool, the machine precisely cuts the material, ensuring clean and sharp edges. The key advantage of using a V-Grooving machine lies in its precision and consistency—each groove is perfectly aligned, creating uniformity across all pieces.

Manufacturers in the metal, wood, and composite industries particularly appreciate the machine’s capacity to handle a wide range of materials, each with different thicknesses and properties. Whether it’s for intricate metal work in the automotive industry or refined wood paneling in the furniture sector, this machine excels at accommodating diverse demands.

Unmatched Precision and Efficiency

The V-Grooving machine’s primary strength lies in its precision. Unlike traditional grooving methods, which may introduce inconsistencies or imperfections, this machine ensures that each cut is flawless. In industries where even the slightest deviation can lead to defects, the reliability of the V-Grooving machine is a game changer. It delivers exact measurements with minimal margin for error, making it a crucial asset in sectors that require tight tolerances.

In addition to its precision, the machine is designed to optimize efficiency. It cuts through materials quickly, allowing manufacturers to maintain high throughput without sacrificing quality. As demand for faster production cycles increases, the ability to produce large volumes of perfectly grooved materials in a short period makes the V-Grooving machine indispensable. With automation capabilities in modern machines, operators can achieve higher levels of productivity while reducing the likelihood of human error.

Cost-Effectiveness and Versatility

While the initial investment in a V-Grooving machine may be considerable, its long-term benefits far outweigh the costs. The durability of these machines ensures that they remain operational for extended periods, reducing the need for frequent replacements or repairs. Additionally, the machine’s versatility allows manufacturers to use it for a wide range of applications, from creating grooves in metal sheets to engraving designs in plastic panels. This flexibility makes it an essential tool in diverse manufacturing environments, saving companies both time and money.

Moreover, the machine’s efficiency translates directly into cost savings. With the ability to perform tasks faster and more accurately than manual labor, companies can reduce waste, optimize material usage, and streamline operations. This combination of precision and efficiency leads to higher profit margins, a crucial factor in today’s competitive manufacturing landscape.

Applications Across Industries

The uses of a V-Grooving machine extend beyond mere aesthetics. In the automotive industry, for instance, it is used to create intricate designs in metal sheets, which are then assembled into various components of vehicles. In the electronics industry, it allows for precise cuts in metal and composite panels, which are vital for constructing circuit boards and housing for electronic devices. The construction sector, too, benefits from the machine’s ability to carve grooves in panels and materials used for interior and exterior designs.

Additionally, the V-Grooving machine is indispensable in industries where lightweight yet strong components are required. The grooves created help to reduce the overall weight of the material while maintaining its structural integrity, making it a perfect solution for applications in aerospace and high-performance machinery.

The V-Grooving machine’s unparalleled precision, efficiency, and versatility make it an essential tool in the manufacturing process. By enhancing the flexibility of materials and offering superior cutting accuracy, this machine helps industries keep pace with growing demands for quality, speed, and innovation. For manufacturers looking to stay competitive in a rapidly evolving market, investing in a V-Grooving machine is not just an option—it is a necessity. The future of manufacturing is built on precision, and the V-Grooving machine is leading the charge.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى