What Is a Grooving Machine? Types, Uses, and How to Choose

2025-08-29

In the world of manufacturing and metal fabrication, precision is everything. Creating a perfect, consistent groove in a piece of material is a fundamental operation that can make or break a final product. This is where the grooving machine comes in—a specialized piece of equipment designed for accuracy, efficiency, and repeatability. Whether you’re a seasoned engineer, a machine shop owner, or simply curious about industrial processes, understanding grooving machine is key to appreciating how countless everyday objects are made.

What is a Grooving Operation?

At its core, grooving is a machining process that involves cutting a narrow channel or “groove” into a workpiece. This is distinct from general turning or milling because it requires a tool with a specifically shaped insert to achieve a clean, precise cut with well-defined walls and floor. These grooves serve critical functions:

- Seating for Seals: O-rings and gaskets are seated in grooves to create airtight or watertight seals in hydraulic cylinders, pistons, and pipe fittings.

- Snap Rings and Retaining Rings: Precision grooves house circlips and snap rings that hold bearings or other components securely in place on a shaft or inside a housing.

- Thread Relief: Grooves are machined at the end of a thread to allow a nut to be tightened fully against a shoulder and to give the cutting tool a clean exit point.

- Parting Off: A specific type of grooving operation, known as cut-off or parting, is used to sever a finished part from the main bar stock.

- Decorative and Functional Patterns: Grooving can also create decorative fluting or functional patterns for improved grip, as seen on tool handles or rollers.

Types of Grooving Machines

There isn’t a single machine called a “grooving machine.” Instead, the grooving operation is performed on various machine tools, each suited to different applications and production volumes.

1. Lathes (CNC and Manual)

The most common platform for grooving is the lathe. A cutting tool moves radially into a rotating workpiece to create grooves on the outside diameter (OD grooving) or the inside diameter (ID grooving). CNC lathes are exceptionally well-suited for this task due to their programmable precision. They can control the tool path, feed rate, and depth of cut with extreme accuracy, allowing for complex groove profiles and high-volume production with consistent results.

2. Milling Machines (CNM and Manual)

While lathes are for rotating parts, milling machines groove stationary workpieces using a rotating cutting tool. This is essential for creating keyways (a specific type of groove) in pulleys and gears or for long, linear grooves in flat plates. A CNC milling machine can perform incredibly complex grooving patterns that would be impossible on a lathe.

3. Dedicated Pipe Grooving Equipment

In plumbing, HVAC, and fire protection industries, a pipe grooving machine is a specialized tool for forming a groove near the end of a metal pipe. This is often a roll grooving process, where hardened rollers cold-form the groove into the pipe without removing material, preserving its strength. These grooves are used with coupling housings to create a strong, leak-proof joint quickly, making them indispensable for large-scale piping projects.

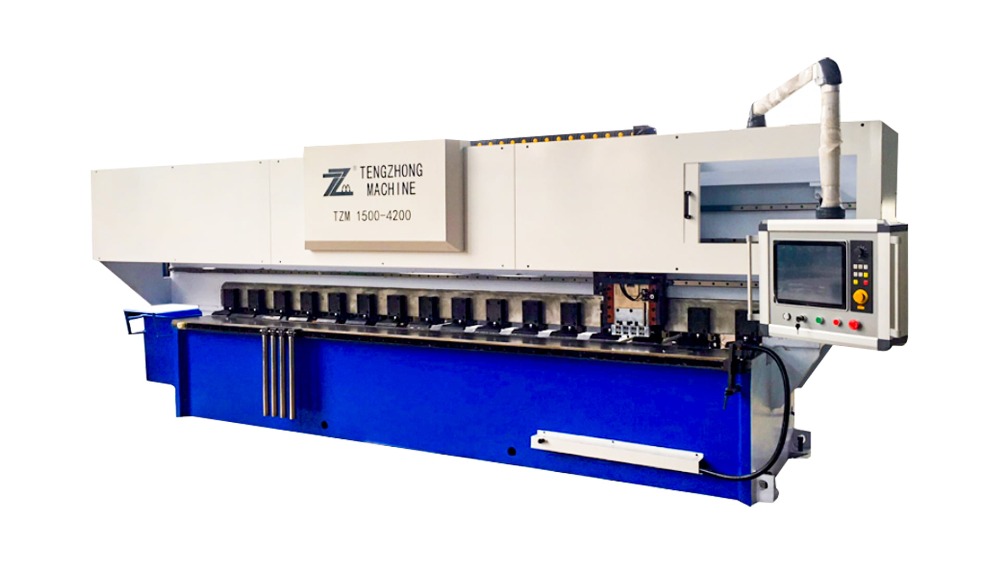

4. Specialty and CNC Machining Centers

For mass production of specific parts like piston rings or compressor components, manufacturers may use dedicated specialty grooving machines designed to perform only that task with maximum speed and efficiency. Furthermore, modern 5-axis CNC machining centers can perform grooving operations on complex parts in a single setup, combining turning, milling, and grooving into one seamless process.

Key Applications and Industries

The application of grooving machines is vast and touches nearly every heavy industry:

- Automotive Manufacturing: Grooving is used to create piston grooves, valve stems, transmission components, and axles.

- Aerospace: High-precision grooves are machined into landing gear components, turbine shafts, and hydraulic systems where failure is not an option.

- Oil and Gas: Massive pipes, valves, and drilling equipment rely on robust grooving for pressure-rated connections and seals.

- General Industrial Manufacturing: From pumps and motors to conveyor rollers and agricultural machinery, grooved components are everywhere.

How to Choose the Right Grooving Process

Selecting the right machine and method depends on several key factors:

- Workpiece Material: The material being cut is the primary deciding factor. Hardened steels require different tool geometries and cutting parameters than soft aluminum or brittle plastics. Carbide inserts are common for their wear resistance.

- Type of Groove: Consider the groove’s geometry—its width, depth, and profile (square, round, v-shaped). A simple O-ring groove can be done on a basic machine, while a complex T-shaped groove might require a special tool and a CNC path.

- Production Volume: For a one-off prototype, a manual lathe or mill might suffice. For a production run of 10,000 parts, the speed and automation of a CNC lathe are necessary for economic viability.

- Precision Requirements: What are the tolerances for the groove’s width, depth, and surface finish? High-precision applications demand rigid, high-end machines and sharp, high-quality tooling.

- Budget: This includes not only the initial machine investment but also the cost of tooling, maintenance, and operator training.

Best Practices for Effective Grooving

To achieve a perfect groove and extend tool life, follow these guidelines:

- Use the Right Tool: Select a tool holder and insert that match the exact width and profile of the groove you need. This avoids the need for multiple passes that can reduce accuracy.

- Secure Tool Holding: Vibration is the enemy of grooving. Use a rigid setup with minimal overhang to ensure stability and prevent chatter, which ruins surface finish and can break the tool.

- Optimize Coolant and Chip Evacuation: Grooving creates a lot of heat and confined chips. Effective coolant delivery is crucial to control temperature and wash away chips to prevent them from recutting and damaging the workpiece or tool.

- Program Correct Feeds and Speeds: Refer to manufacturer recommendations for your specific tool and material. Starting with too aggressive a cut is a common cause of tool failure.

Conclusion

From the car you drive to the water in your home, grooving machines play a silent but vital role in creating the reliable components that modern society depends on. Understanding the different types of machines for grooving, their applications, and the principles behind a successful grooving operation empowers manufacturers to choose the right technology for their needs. By investing in the correct process and adhering to best practices, shops can achieve new levels of quality, efficiency, and profitability in their machining workflows.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى