Precision in Motion: The Hydraulic 3 Roller Rolling Machine

2025-06-13

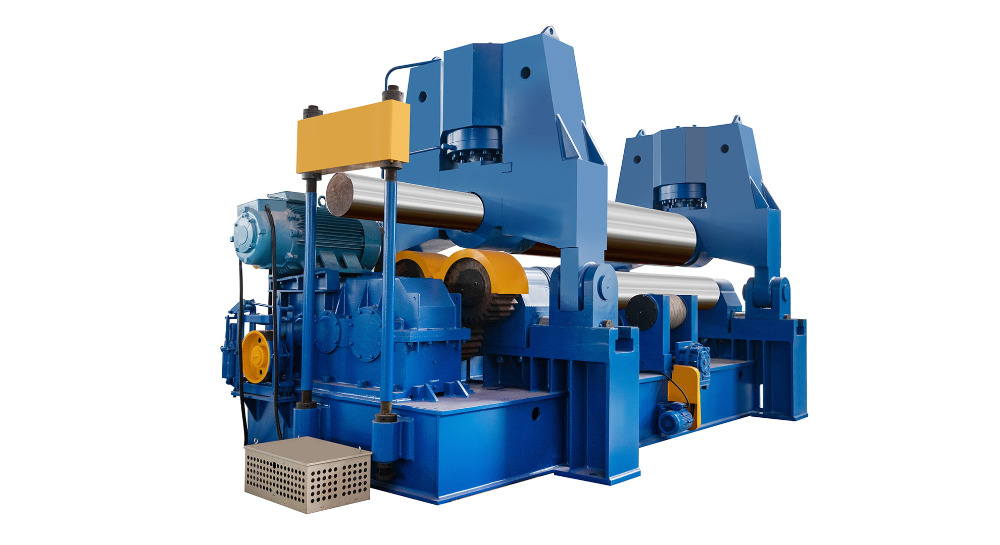

In the realm of metal fabrication, few machines deliver the balance of brute force and surgical accuracy quite like the hydraulic 3 roller rolling machine. Designed to shape sheets of steel, aluminum, and other metals into precise cylindrical forms, this powerhouse stands as a cornerstone in industries that demand excellence—shipbuilding, pressure vessel production, automotive manufacturing, and beyond.

Engineering Prowess Meets Practicality

At its core, the hydraulic 3 roller rolling machine operates on a deceptively simple principle: leverage and controlled pressure. Yet, what elevates it above conventional rolling systems is its tri-roller configuration—one top roller and two adjustable bottom rollers—coupled with the force-multiplying advantage of hydraulic power.

This dynamic trio works in harmonious synchronization. The top roller exerts downward pressure, while the bottom rollers rotate to pull and bend the metal sheet into a uniform arc. Unlike mechanical models, the hydraulic system allows for precision-tuned adjustments on the fly, optimizing pressure and alignment for varied materials and thicknesses. The result? Seamless curves, minimal flat spots, and exceptional repeatability.

Uncompromising Versatility

Adaptability is the hydraulic 3 roller machine’s quiet strength. Whether you’re working with ultra-thin sheets or thick industrial plates, this machine accommodates with graceful authority. Standard configurations can handle plate widths up to 3,000 mm and thicknesses as robust as 50 mm, depending on the build. Optional CNC controls can further elevate its capabilities, bringing digital finesse to analog power.

The hydraulic system provides more than just muscle—it adds intelligence. Load sensing, auto-correction, and programmable rolling sequences drastically reduce material waste and production time. This translates into not only tighter tolerances but also increased productivity across the board.

Built for the Long Haul

Constructed with hardened steel rollers and a fortified frame, these machines are engineered for longevity in high-volume production environments. The robust design minimizes deflection, even under extreme loads. Low-maintenance hydraulic circuits, sealed bearings, and integrated lubrication systems further enhance reliability and reduce downtime.

But durability doesn’t come at the cost of operator safety. Modern hydraulic 3 roller machines incorporate advanced safety interlocks, emergency stop systems, and ergonomic control panels. The machine isn’t just a tool—it’s a partner in production, designed to protect its operators while delivering uncompromising results.

Precision Without Compromise

In an age where accuracy and efficiency can dictate a project’s success or failure, the hydraulic 3 roller rolling machine delivers uncompromising precision. Its symmetrical roller design ensures consistent rolling arcs, reducing the need for post-process correction. The pre-bending function—a hallmark of hydraulic models—eliminates unwanted flat zones at sheet ends, allowing for a more complete and visually clean cylinder.

This exactitude is not just technical—it’s economical. Higher first-pass yields and reduced rework translate into lower operational costs and quicker turnaround times. When precision becomes a financial asset, this machine becomes indispensable.

Applications That Span the Spectrum

From HVAC ducts to submarine hulls, the applications are as varied as they are demanding. Pressure vessels, storage tanks, wind tower segments, and aerospace components all benefit from the machine’s versatile forming abilities. In industries where precision shapes function—and safety—there’s no room for compromise.

The Intelligent Muscle of Metal Forming

The hydraulic 3 roller rolling machine is more than a piece of equipment—it’s the fusion of engineering sophistication and manufacturing muscle. It doesn’t just bend metal; it sculpts performance. For operations that demand tight tolerances, rugged dependability, and adaptable precision, this machine stands as a strategic asset. With every rotation, it proves that in metal forming, power is nothing without control.

English

English русский

русский Français

Français Español

Español Português

Português عربى

عربى